Why Pick Specialist Welding Inspection Madison for Your Projects

Wiki Article

The Importance of Thorough Welding Assessment in Industrial Applications

In the realm of commercial applications, the importance of meticulous welding inspection can not be overemphasized. It plays a necessary role in ensuring the structural honesty and long life of welded elements. Advanced non-destructive screening techniques permit the early discovery of prospective problems, such as fractures and insufficient blend, which, if left unchecked, might bring about tragic failures. Adherence to strict market requirements not just assures high quality however also develops customer confidence. As we check out the complex advantages of diligent welding evaluations, one need to take into consideration the broader implications on security, reliability, and cost-effectiveness in commercial operations.Enhancing Structural Integrity

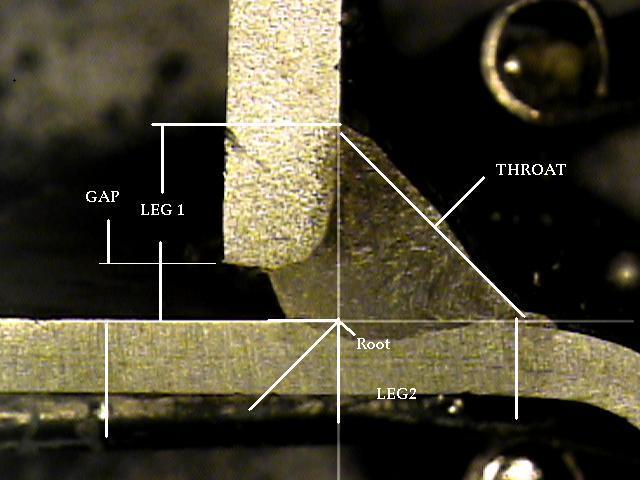

When it comes to welding inspection in industrial applications, enhancing architectural stability is extremely important. The key objective of welding inspection is to make certain that the welds are qualified of birthing the expected stress and anxieties and tons they will run into in service. This includes a detailed examination of the welds' dimensions, alignment, and total top quality, ensuring they satisfy the specified requirements and codes. Precise assessment methods, such as aesthetic inspection, ultrasonic testing, and radiographic screening, are essential in recognizing problems that could jeopardize the framework's safety and performance - Welding Inspection Madison.The significance of maintaining structural stability in bonded structures can not be overemphasized. Inadequately executed welds can cause disastrous failures, resulting in expensive repair work, downtime, and also endangerment of human lives. Inspectors play an essential function in the lifecycle of commercial components, offering guarantee that the welding process supplies the preferred stamina and longevity.

Additionally, advanced modern technologies, such as phased array ultrasonic screening and electronic radiography, deal improved capabilities in discovering potential weaknesses, permitting for rehabilitative actions prior to concerns rise. By prioritizing the stability of welds via meticulous examination, industries can make sure operational efficiency and extend the durability of their framework.

Recognizing Welding Problems

Identifying welding problems is an essential facet of guaranteeing the security and dependability of bonded structures. Common welding problems consist of porosity, fractures, incomplete blend, and damaging.

Competent inspectors make use of both visual examination and advanced non-destructive screening (NDT) approaches, such as ultrasonic or radiographic screening, to find these problems. The prompt identification and correction of welding issues are critical to preserve the structural integrity and longevity of commercial components.

Making Certain Conformity Requirements

Conformity with well established standards, such as those given by the American Welding Culture (AWS) and the International Organization for Standardization (ISO), makes sure that welds satisfy minimal safety and security and top quality requirements. These standards encompass a vast range of criteria, consisting of material specifications, welding procedures, and qualification of welders.

Regular audits and inspections are vital in verifying compliance. Assessors have to have a comprehensive understanding of the pertinent standards and be adept at utilizing different non-destructive screening (NDT) methods to review weld top quality. By making certain that welding practices line up with conformity requirements, companies reduce the danger of non-conformity, which can lead to lawful liabilities and safety dangers.

In addition, keeping conformity not just safeguards architectural stability however likewise boosts a business's reputation in the industry. Stakeholders and customers are most likely to trust fund companies that consistently demonstrate a commitment to quality and safety through strenuous compliance. Thus, ensuring compliance criteria is a critical element in the effective execution of welding in industrial applications.

Minimizing Maintenance Prices

The application of innovative non-destructive screening (NDT) approaches, consisting of ultrasonic, radiographic, and magnetic particle evaluations, boosts the capability to spot subsurface flaws without compromising the architectural integrity of elements. By employing these strategies, industries try this website can dramatically prolong the solution life of their tools, lowering downtime and the associated economic concern of maintenance activities.

Moreover, a durable welding inspection regime supports the optimization of maintenance schedules, moving from reactive to predictive maintenance techniques. This proactive method not only stops unexpected failures yet additionally enhances resource allocation, making sure that upkeep efforts are focused and effective. Inevitably, the investment in extensive welding assessment is offset by the substantial savings realized via reduced upkeep demands, adding positively to the overall functional efficiency of commercial enterprises.

Improving Precaution

Although safety and security is a vital problem in commercial procedures, accomplishing ideal safety standards calls for a devoted concentrate on the quality and integrity of bonded structures. Welding examination plays a critical role in this context, as it makes certain that all joints and connections meet stringent safety standards. Comprehensive assessments aid determine issues such as cracks, porosity, or incomplete combination that can jeopardize architectural honesty. Such problems, if left unaddressed, position substantial dangers, potentially leading to devastating failures.To enhance safety and security procedures, embracing advanced non-destructive testing (NDT) techniques is necessary. Methods like ultrasonic testing, radiographic testing, and magnetic fragment evaluation enable in-depth assessment without harming the structure. These innovations make it possible for assessors to detect surprise imperfections early in the building and construction procedure, helping with prompt restorative actions. Implementing a durable quality control system that consists of normal training for welders and inspectors makes certain adherence to established security criteria.

Finally, promoting a society of safety within the organization stresses the value of comprehensive welding examinations. Motivating open interaction and partnership amongst welders, engineers, and assessors adds to a shared dedication to security excellence. Welding Inspection Madison. In doing so, industries can guard their operations, shield workers, and preserve public count on

click to read

Final Thought

Thorough welding examination is essential in commercial applications, dramatically improving structural integrity and reliability. Eventually, the diligent implementation of welding assessments plays a vital duty in preserving operational performance and safety and security in industrial setups.As we check out the complex advantages of attentive welding inspections, one must think about the broader effects on security, integrity, and cost-effectiveness in commercial operations.

The primary goal of welding examination is to make sure that the welds are qualified of birthing the expected tons and stress and anxieties they will certainly run into in service. Effective welding assessment plays an essential role in minimizing these costs by ensuring the honesty and durability of welds, thereby minimizing the risk of premature failings.Thorough welding assessment is essential in industrial applications, substantially boosting structural honesty and reliability. Ultimately, the attentive implementation of welding examinations plays an important duty in preserving operational performance and safety and security in industrial settings.

Report this wiki page